PopPet the Robot by Edwards Robotics

As always this is for entertainment and to help stop me going mad.

This Post was Written and Edited on my pcDuino running Ubuntu 14.04.

I updated it on Friday 27/11/2015 about the Bluetooth Operation.

Some eight months ago I ordered a robot from Edwards Robotics that was fully funded by Kickstarter and was in the final stages of being prepared for delivery to the people who funded the project first, then people like me who purchased via the PopPet The Robot site would be next on the list of deliveries and true to my form I started to get worried that I had been played for a fool and had lost my $120.00, so I sent off a not so pleasant email which got a very nice reply and an offer was made to refund me or wait just a little longer and the Kit for the Robot would soon be packaged and sent out. I agreed to wait and in the reply he said that he would add something extra for the long wait, I thought well okay at least he is trying to make up for the extra wait, to my surprise it arrived the other day, only a week or so after his reply and true to his word I did in fact get a little extra, actually I got a Huge Amount Extra, he sent me the V2 Bluetooth version and it is amazing, for $120.00 (not sure what the current price is) it is excellent value for money, it meets and exceeds all my expectations and after a few initial hiccups I got it working and it does everything the instructions say it will do, I have not at this point in time (24/11/2015) set up the Bluetooth operation but by the time this goes to print I hope to have it setup and tested. So let me show you the product and give you an honest appraisal of PopPet The Robot V2 Bluetooth as it was delivered to me in Kit Form. This is for this kit only and does not mean all kits will be sent out like this one.This Post was Written and Edited on my pcDuino running Ubuntu 14.04.

I updated it on Friday 27/11/2015 about the Bluetooth Operation.

PopPet V2.0 Bluetooth by Edwards Robotics

The complete instructions can be viewed on line at www.poppettherobot.com as can all the detailed information, even the files for making the chassis components at home or at least they were. The sketches required to set up the sensors and the final sketches required to get PopPet up and running are there for you as well, all of it is Open Source and is Arduino Compatible.

PopPet's Box

As noted above the kit doesn't have any paperwork in it because it is all available from the PopPet Home Page listed above and is very easy to locate and read, the layout and information is excellent and if you follow them step by step you will get a robot up and running with a minimum of fuss.

The kit is normally complete and all the components required to assemble are included in the kit, my kit however was missing the bag of nuts, screws and or fasteners BUT this wasn't a problem for me as I have an extensive number of fasteners here so I was able to continue without delay.

PopPet Unpacked

The laser cut components look fantastic an the initial inspection was very promising and they fitted together perfectly and all other components were in the kit. I was extremely pleased with the length of the USB cable, it meant that I could have it sitting in front of me while connected to the computer, I hate the short leads that normally come with the Arduino Clones out there. Okay the next step for me was to look at all the steps in the construction process to make sure that I had a good idea of what was to come and made a note of any special steps so that I could pre-empt them as I went through the build.

PopPet out of the Bags

One of the things that gives me the s#!^s is a project that doesn't follow a set wiring colour code and I was very pleased with the wiring information given in the instructions, the wiring diagram was excellent, I printed it out and made sure that I got it right first time so that I wouldn't damage the electronic components, mind you they are a bit forgiving but can still be easily damaged take care to read and follow it carefully.

Now to the electronic components, I always have a very close look for electrical problems, after 42 years as an automotive electrician I know how easy it is to overlook even the basic things so I very carefully inspect all components, lucky I did in this instance, the Brain as it is called on the PopPet site was not up to my standard, the soldering left a lot to be desired, some of the through hole components or pins actually were so badly soldered I could see light through them, I think it would have worked but for how long was my worry, this didn't present a big problem to me as I am very experienced at component level repairs and soldering and I set about re-soldering all the suspect joints, a good clean first and the solder applied as required and all worked perfectly.

PopPet's Brain (Dagu Arduino Mini Driver Board Clone?)

PopPet's Brain is an Arduino Compatible Two Motor full H Bridge Mini Controller that makes the whole thing so easy to build, program and wire up and the size is perfect for this style of project, in general it was nicely made except for the above mentioned aspect but that aside is was perfect for the job.

As I mentioned I was upgraded to the V2 Bluetooth Kit and the Bluetooth is the normal fully self contained unit that simply plugs into the Mini Driver Board on the inline header pins at the center of the board just in front of the main IC at the USB connector end, BUT don't plug it in untill you have downloaded the Sketch to the brain otherwise you will have problems with programming.

The Bluetooth Module

The construction is made very easy by the use of laser cut MDF that looks great as a result of the burnt look, once finished it really is a great looking robot. The mounting of the motors is easy as is the construction of the wheels also made of three sections of MDF and a rubber "O" ring for the tyre that is simply screwed together. I have used the same construction method in a few of my robots as well, just so simple. You can see the wheels in the third image in this post.

The HC-SR04 Ultrasonic sensor

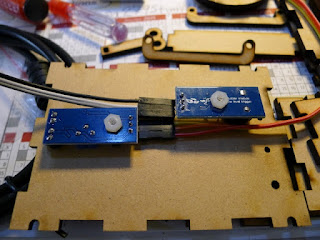

The IR Sensor

The Piezo Buzzer

The use of standard Arduino Shields makes the robot easy to build, wire up and write a sketch to suite because of the Libraries that are available, the number out there never ceases to amaze me and the general quality is fantastic to say the least. I did run into another problem during construction and that was with the battery holder, it had an open circuit in the earth or negative wire, the crimp wasn't done correctly but was very easy to find and repair so no real problem but had me guessing for a second or two.

The IR Sensor and Piezo Buzzer on the base Plate

The Battery support and center Plate fitted

Note in the image above that the wiring is routed through gaps in the center plate and are positioned to make it easy to connect all the components together. The lower plate in the above image is the battery support, the Motors at the front supply the other support, simple solution to mount the battery box in a small space, well done.

The Sound Holes on Left and IR Sensor on Right

The above image shows the sound holes, left and IR sensor slots, far right but it also gives access to the adjustment trim pot for the sensor, this is done for all the sensors that need to be adjusted and makes it so easy to set it all up, some very good solutions included in the design to make it very easy to build. You can also see the mini ball castor on the far left, make sure you don't over-tighten the mounting screws as it can deform and stop the ball rotation, I know because it happened to me and my heavy hand. One little thing to note in my construction is that I didn't use screws and nuts to hold the wheels together, have a look at the finished product images at the end, I used Roll Pins, made of metal and because of the spring loading as you insert them they hold the wheels together very well but I would use what is supplied in the kit for normal construction, I only used them because I had some here to spare and they were the perfect size.

The little DC Motor mounted low in the chassis

I have to say that the overall design is excellent, it is obvious that the extra time taken to deliver the kit was taken up in design improvements and V2.0 really is a great product.

PopPet's Face, cheeky little thing

Two of the setup sketches didn't compile in my version of the Arduino IDE, I have the very latest version and it makes note of the fact that the sketches are better suited to an older version of the IDE so I did the tests and setup on my Banana Pi with Ubuntu and the older version of the Arduino IDE in it which worked perfectly, mind you I did do the final program or Sketch Upload on the Windows Laptop and it worked perfectly from that as well so do some sketch work to learn how to write a sketch, that is the best way for me, use the many sketches out there and make them work for my project, great fun when you achieve what you want then share it with the community when you finish.

The kit as sent to me was lacking in finish quality and some parts but that didn't worry me greatly as I had enough parts to complete the build and the build quality of the brain was a little less than perfect but once again it most likely would have worked but for how long was anyone's guess but once again it wasn't a problem for me as I enjoy the challenge of the build. Also the fact that two of the setup sketches didn't compile wasn't a problem as it gave me another challenge as well, because it made me think about why they wouldn't work and that in itself taught me a lot about sketches, BUT and there is always a but, if someone else got this kit it would have been a problem, especially if they were new to Arduino, robotics and electronics so for that reason I'm giving this kit 6 out of 10, if all the components were in the kit and it had no other concerns it would have deserved 9.5 out of 10 at least and when you consider that it is a young Australian who designed and built the kit from scratch and is marketing it to the world he is destined for great things and I give him a perfect score, 10 out of 10. A job very well done and a lot of fun building, debugging and testing my PopPet the Robot.

The kit as sent to me was lacking in finish quality and some parts but that didn't worry me greatly as I had enough parts to complete the build and the build quality of the brain was a little less than perfect but once again it most likely would have worked but for how long was anyone's guess but once again it wasn't a problem for me as I enjoy the challenge of the build. Also the fact that two of the setup sketches didn't compile wasn't a problem as it gave me another challenge as well, because it made me think about why they wouldn't work and that in itself taught me a lot about sketches, BUT and there is always a but, if someone else got this kit it would have been a problem, especially if they were new to Arduino, robotics and electronics so for that reason I'm giving this kit 6 out of 10, if all the components were in the kit and it had no other concerns it would have deserved 9.5 out of 10 at least and when you consider that it is a young Australian who designed and built the kit from scratch and is marketing it to the world he is destined for great things and I give him a perfect score, 10 out of 10. A job very well done and a lot of fun building, debugging and testing my PopPet the Robot.

If your into Arduino, Robots and Electronics then you must get yourself a PopPet.

The ON, OFF switch

Now that I have had PopPet running for a while I did find the switch setup a bit of a problem in that the robot kept hitting it and turning itself OFF, not a big problem but one that I will overcome by making a small shield for it so it doesn't happen. The sensors work well and I love the fact that it turns off if my grandson picks it up, he likes to play with the wheels as they turn, now all I need to do is stop him from wanting to push it. I did a short video and took a few images of it finished and as I said before you must get yourself one of these robots, it is a great little project.

Update; 27/11/2015.........

I did a test on the Bluetooth Operation of PopPet which was easy to set up and get going. I uploaded the Bluetooth Sketch to PopPet and then fitted the Bluetooth Shield to the Mini Board, I loaded the app to my Android Tablet, one of those cheap Pendo units that I purchased some months ago for use with my Arduino's and the like and it took two attempts to pair them but once it did it all worked very well for about five minutes and then it locked up, you could hear the motors trying to go all the time but that was all. Not a big problem as all I had to do was restart the app and away PopPet went. The different modes and the way it talks is excellent and they all worked very well, the dot that works like a joystick was about the best in my books but the explorer mode was excellent as well, the grandkids will love it when they come over on the weekend.

So the final verdict is 9 out of 10, a very well thought out robot kit that will give everyone from the youngest to oldest robot builders out there a lot of fun building and using and more to the point modifying the sketches to get it to do other things or just developing your own, however you do it it will be a lot of fun.

Update; 27/11/2015.........

I did a test on the Bluetooth Operation of PopPet which was easy to set up and get going. I uploaded the Bluetooth Sketch to PopPet and then fitted the Bluetooth Shield to the Mini Board, I loaded the app to my Android Tablet, one of those cheap Pendo units that I purchased some months ago for use with my Arduino's and the like and it took two attempts to pair them but once it did it all worked very well for about five minutes and then it locked up, you could hear the motors trying to go all the time but that was all. Not a big problem as all I had to do was restart the app and away PopPet went. The different modes and the way it talks is excellent and they all worked very well, the dot that works like a joystick was about the best in my books but the explorer mode was excellent as well, the grandkids will love it when they come over on the weekend.

So the final verdict is 9 out of 10, a very well thought out robot kit that will give everyone from the youngest to oldest robot builders out there a lot of fun building and using and more to the point modifying the sketches to get it to do other things or just developing your own, however you do it it will be a lot of fun.

The Short Video